Ebara in-line pump SSLD type

Even one small pump brings big energy-saving efficiency!

●It is a slash with CO2

The forest of the Tokyo Dome ground area 1.8 times equivalency is the same as an effect to absorb CO2

●It is energy saving by simple construction

●I invest it in a short term and collect it

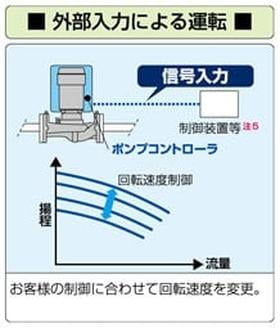

I remove useless pressure when I change the LPD type from the bubble control (koteisokuundo) to rotary, controlling the speed with the inverter and can plan energy saving.

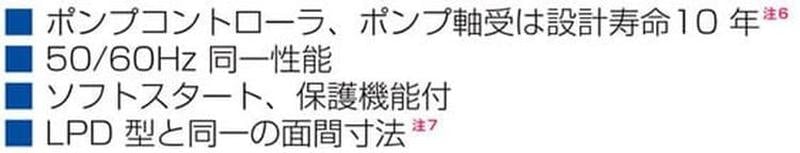

Because up to 18 points of general efficiency is improved than an LPD type other than rotary, controlling the speed with the implemented pump controller, the SSLD type becomes the energy saving more.

High efficiency pump adoption

I largely improved pump efficiency by the new impeller which I made use of an Ebara's original analysis technology in, the adoption of the casing.

The PM motor deployment

I promote saving energy by efficiency to exceed a high efficiency instruction motor (JIS C 4212).

Reverse elucidation flow analysis of the three-dimensional impeller

Performance comparison with the current LPD type

Motor efficiency comparison

It is about 54% of energy-saving effects at diameter 50-3.7kW

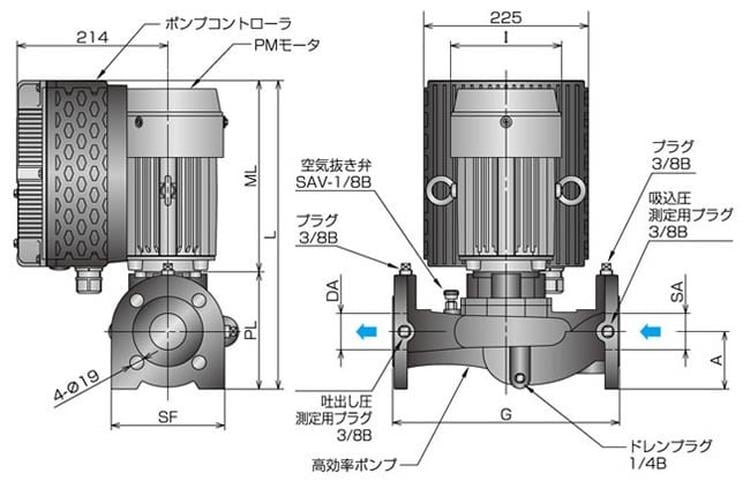

Figure of external form dimensions

Standard specifications

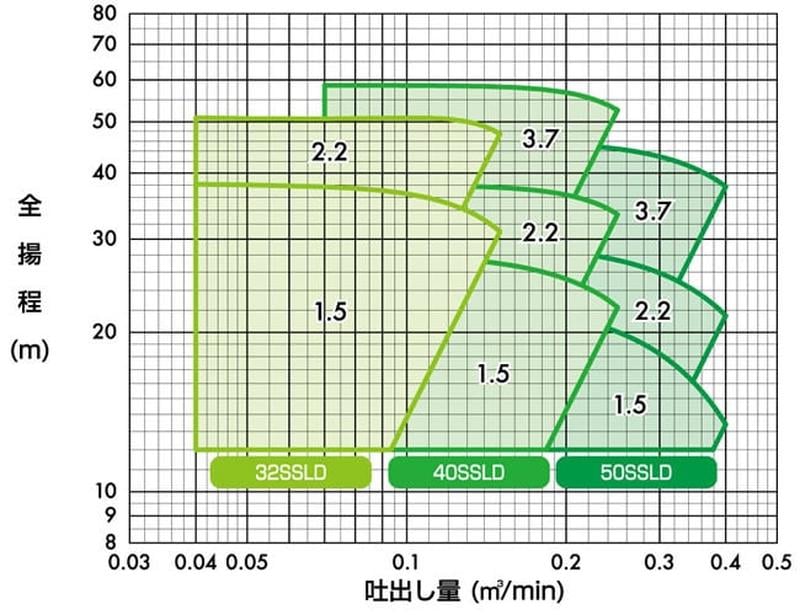

Figure of choice

Essential points list

※The publication contents may have a change. Thank you for your understanding beforehand.