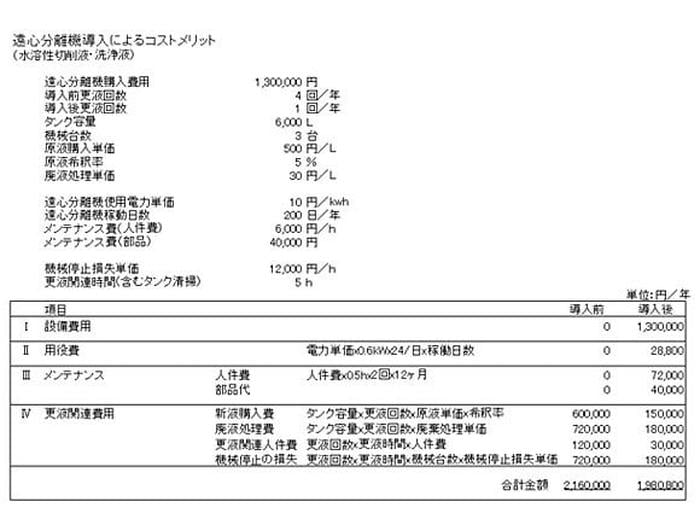

Before the disposal examination of the reuse

The disposal of washings is necessary for certain surface treatment required for industry with the metalwork.

Not only I say merely environmental protection, but also the disposal of washings enables a big cost cut in the long term.

Cutting oil handles cutting oil life to 4-5 times using a centrifuge

Centrifuge introduction merit

・Cutting oil life to 4-5 times

・Shortening of the machine stop time

・Large reduction of the cutting oil purchased amount

・Large reduction of the cutting oil disposal expense

・Improvement (bad smell prevention) of working conditions

[main characteristic]

・Large reduction of the washings purchase expense

・Large reduction of the waste fluid processing expense

・I always keep washings by the circulation cleanliness neatly

・Solid content and the oil are concentrated, and quantity of outbreak is reduced

・It is stable, and a superior surface treatment effect is provided

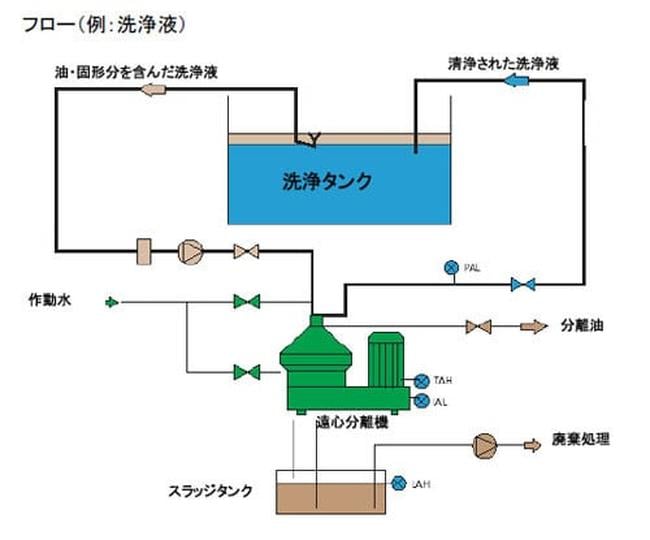

Basic operation

1.The dirty cutting oil is supplied to the centrifuge with a separate placement pump.

2.A body of rotation which incorporated a separation board for the separation of the liquid clearness and mixture is incorporated in a centrifuge.

3.The liquid is separated by specific gravity in the centrifuging ground in the body of rotation which is supplied, and rotates at high peed by the entrance.

4.In the case of water-soluble cutting oil, the separated cutting oil is discharged under the pressure by the upper part exit.

The surfacing oil is exhausted by overflow outside a plane.

5.The separated solid content is eliminated after the stop by hand, or it is exhausted automatically while driving by a model.

Washings and drawing oil

The centrifuge is the method that is effective for the disposal of washings. It is adopted for disposal of removal of fat tank and drawing oil heated with a centrifuge. Monthly steel materials from 7,000 to 9,000 tons are used in a certain factory. Those steel materials are pressed by power of 2,000 tons and reach the temperature of 2,000 degrees for friction and pressure locally. Therefore, oil is sprayed with spray. Degree of abrasion and the shear is lowered by dispersion of the oil and, as a result, increases the life of the tool and can give the processing precision of parts. As for the korareno parts, it is removed fat before performing a post-process such as welding and the painting.

The removal of the oil

Heated alkali washings are used for the removal of fat, Plural tanks are used in the removal of fat process.

Removal of fat plays biggest role in two tanks of the beginning in them and is heated to about 75 degrees.

I decrease and wash surface tension with density 5% alkali washings by the removal of fat tank.

A bypass is clean and uses the centrifuge of the waist F rear to remove surfacing oil and metal powder.

I reduce the influence that I always wash liquids in a tank, and oil gives for a production process by the bypass cleanliness.

The deterioration of washings is controlled by the removal of the surfacing oil and leads to the extension of life of washings.

Temporary rust prevention measures are performed to prevent rust in the atmosphere time to around a painter at the final stage of the washing process.

Removal of fat plays biggest role in two tanks of the beginning in them and is heated to about 75 degrees.

I decrease and wash surface tension with density 5% alkali washings by the removal of fat tank.

A bypass is clean and uses the centrifuge of the waist F rear to remove surfacing oil and metal powder.

I reduce the influence that I always wash liquids in a tank, and oil gives for a production process by the bypass cleanliness.

The deterioration of washings is controlled by the removal of the surfacing oil and leads to the extension of life of washings.

Temporary rust prevention measures are performed to prevent rust in the atmosphere time to around a painter at the final stage of the washing process.

From the disposal to recycling: Large reduction of the disposal expense

I keep an oil content concentration low, and the mixture supplied to the centrifuge is separated to three levels continually by a surfacing oil collection.

The solid content containing some washings, the second do not include oil and most oil, but the first is supplied to the last processing equipment such as ultrafilters.

The separated oil is sent to the mixing tank; such as additives is adjusted more, and is reused.

And the surfacing oil collected from a washing tank is reused as drawing oil.

The solid content containing some washings, the second do not include oil and most oil, but the first is supplied to the last processing equipment such as ultrafilters.

The separated oil is sent to the mixing tank; such as additives is adjusted more, and is reused.

And the surfacing oil collected from a washing tank is reused as drawing oil.

※The product specification mentioned above is data as of July, 2008. Please note that specifications, the production situation of the product may be changed without a notice.